Innovations in rc excavator Technology to Watch in the Future

Wiki Article

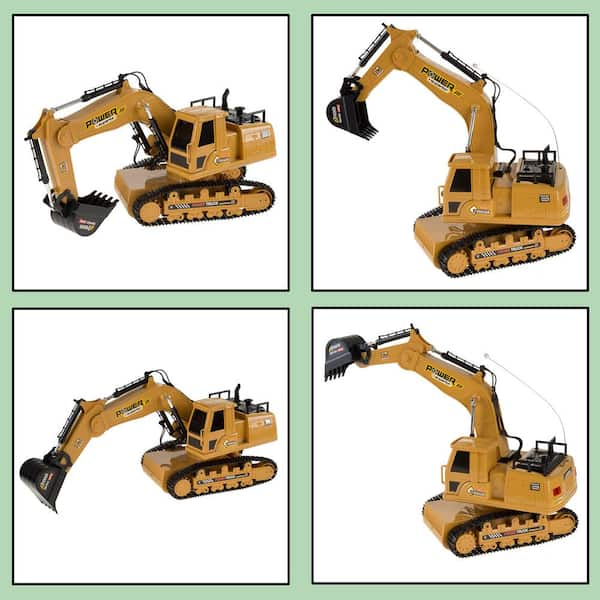

The Crucial Attributes of Excavator That Make It a Must-Have Device

Excavators are important in the construction and landscaping sectors. Their versatile attachments permit a variety of jobs, from excavating to demolition. In addition, they boast remarkable excavating deepness and reach, powered by durable engines. Operator convenience and compact styles boost usability in various atmospheres. However, what absolutely establishes excavators apart are their sophisticated hydraulic systems and resilience. Recognizing these attributes can clear up why they are thought about important tools on any type of job site.Flexible Accessories for Boosted Capability

Excavators are effective devices on their very own, the addition of flexible attachments substantially improves their performance. These add-ons transform a basic excavator right into a multi-purpose tool, suitable for a variety of tasks. Containers, for instance, come in various sizes and shapes, allowing operators to dig, scoop, and move products efficiently. Hydraulic thumbs can be included for improved gripping and handling of bulky products, such as logs or rocks.Furthermore, specialized add-ons like breakers and augers allow for exploration and demolition work, expanding the excavator's utility on construction websites. remote control excavator. Grapples are an additional option, ideal for moving and arranging debris. This flexibility not just enhances efficiency however likewise lowers the demand for numerous machines, conserving time and expenses. By furnishing excavators with the right attachments, operators can deal with diverse jobs, making them crucial in the construction sectorSuperior Excavating Deepness and Reach

Excavators are created with superior digging depth and reach, enabling them to navigate in tight spaces and gain access to hard-to-reach areas. This ability is crucial for various building and excavation projects, where standard equipment may fail. With flexible boom arms and extendable tracks, excavators can quickly navigate uneven terrain while maintaining stability.The digging depth can differ significantly amongst versions, typically ranging from 10 to 25 feet, depending upon the layout and objective. This function enables drivers to dig deep into structures, trenches, and various other deep frameworks effectively. In addition, the reach of an excavator allows for accurate excavating and product handling without repositioning the device frequently, conserving time and labor costs.Ultimately, the premium digging depth and reach of excavators make them vital for experts looking for to finish complex tasks with precision and efficiency. Their flexibility enhances performance on task websites, showcasing them as a vital tool in modern-day building and construction.Powerful Engine Efficiency

When it concerns effectiveness and performance on building and construction sites, effective engine efficiency plays a pivotal role in the capabilities of an excavator. A durable engine produces significant horsepower, enabling the device to deal with durable jobs easily - remote control excavator. This stamina converts right into faster cycle times, enabling operators to full tasks extra quickly.Additionally, powerful engines give the required torque to manage difficult terrains and varied tons, ensuring that the excavator can do successfully under various conditions. Whether it is raising, digging, or moving materials, the engine's performance directly affects the general functional efficiency of the machine.Furthermore, advancements in engine modern technology have actually led to boosted fuel effectiveness, minimizing operational prices while keeping power output. Ultimately, the engine's performance acts as the foundation of an excavator, attesting its standing as a crucial tool in the building and construction sector

Advanced Hydraulic Systems

Boosted Raising Ability

A considerable enhancement in raising capability can be connected to innovative hydraulic systems discovered in contemporary excavators. These systems make use of high-pressure liquid to produce greater pressure, permitting drivers to lift much heavier lots with ease. The design behind these hydraulics guarantees peak performance, giving a remarkable power-to-weight proportion that boosts general effectiveness. Consequently, excavators can take on requiring tasks, such as raising big materials or equipment, without jeopardizing security. Additionally, the robust layout of hydraulic components contributes to boosted resilience and dependability, making them suitable for various building settings. This enhanced training ability not only lowers the time needed for jobs however likewise decreases the requirement for extra equipment, verifying crucial for both productivity and cost-effectiveness in the construction industry.Enhanced Accuracy Control

Conventional excavators typically had a hard time with precision, modern hydraulic systems have actually transformed control mechanisms, allowing operators to perform jobs with amazing accuracy. These advanced systems use symmetrical control shutoffs that permit smoother and more responsive movements, significantly reducing the margin for mistake. Operators can now carefully tune the excavator's movements, making it less complicated to navigate limited rooms and take care of fragile products. Enhanced responses systems better notify drivers of real-time efficiency, ensuring excellent control in between the machine and operator. This raised accuracy not only boosts effectiveness but likewise boosts safety and security on work websites, decreasing the danger of mishaps. Because of this, modern-day excavators furnished with advanced hydraulic systems are vital devices for building and construction and excavation projects calling for careful precision.Operator Comfort and Visibility

Operator convenience and visibility are essential components in the design of modern-day excavators (remote control excavator). Features such as ergonomic seat design, boosted presence alternatives, and reliable control designs significantly improve the driver's experience and productivity. Focusing on these facets assurances that operators can work effectively and securely in various problemsErgonomic Seat Design

Convenience and visibility are extremely important in excavator design, with the ergonomic seat playing an important duty in improving the operator's experience. An ergonomic seat is engineered to sustain the driver's body, lowering exhaustion throughout lengthy hours of operation. Flexible her explanation features, such as seat height, back-rest angle, and lumbar support, satisfy private choices and advertise excellent stance. These modifications improve comfort and allow the operator to keep concentrate on tasks without discomfort. In addition, a well-designed seat can give better lateral support, allowing for smoother handling when the excavator functions. This thoughtful design not only enhances productivity however likewise contributes to total security, making certain that operators can perform their obligations efficiently and efficiently.Enhanced Presence Attributes

The design of an excavator expands beyond simply the seat, with improved exposure attributes playing a significant function in operator convenience and overall security. Big home windows and tactically located mirrors supply operators with a clear view of their environments, minimizing blind places. This style consideration enables for far better spatial recognition, which is vital in hectic job settings. On top of that, several excavators include rearview electronic cameras and advanced tracking systems that assist drivers in navigating tight areas. The integration of these exposure features not only advertises safety yet also decreases driver fatigue by enabling less complicated monitoring of workplace. Inevitably, improved visibility adds to more reliable procedures and aids ensure that excavators can do their jobs properly and securely.Control Design Effectiveness

While handling facility work sites, an efficient control format substantially improves both operator convenience and presence. A well-designed control arrangement warranties that drivers can access vital functions with minimal effort, lowering exhaustion throughout lengthy hours. Ergonomic joystick placements and intuitive switch arrangements permit seamless procedure, allowing drivers to maintain emphasis on the task handy. In addition, clear presence of both the job area and the control board is critical for security and precision. Modern excavators commonly incorporate flexible seats and control settings to suit numerous operator preferences, even more enhancing comfort. Eventually, a thoughtfully made control design not just boosts performance yet likewise fosters a much safer working atmosphere by permitting operators to respond quickly to changing conditions.Compact Design for Urban Environments

As city construction websites typically face room constraints, a compact style becomes necessary for excavators operating in these settings. These makers are engineered to browse limited spaces, enabling for reliable maneuverability in jampacked work websites. A decreased impact enables them to work carefully to existing frameworks, lessening disturbance and making best use of productivity.The compact layout typically includes much shorter tracks and a tighter transforming span, helping with operation in slim streets and restricted locations. Lightweight products add to alleviate of transport, making it easier to relocate the excavator from one area to one more within the metropolitan landscape.Additionally, several compact excavators are geared up with features such as functional add-ons and extendable arms, improving their performance while preserving a small dimension. This adaptability allows drivers to deal with a selection of tasks, from digging to demolition, all while suitable flawlessly right into the restrictions of metropolitan atmospheres.

Durability and Maintenance Considerations

Longevity Visit Your URL stands as a vital consider the performance and durability of excavators, particularly popular city atmospheres. These equipments are subjected to strenuous conditions, including varying soil types, extreme temperature levels, and high-frequency usage. Top notch products and robust construction are required for guaranteeing that excavators can withstand these obstacles without compromising functionality.Regular upkeep is equally important in maintaining resilience. Scheduled examinations, timely click now oil modifications, and the replacement of used components contribute considerably to an excavator's lifespan. Operators should additionally pay attention to hydraulic systems, tracks, and undercarriages, as these components commonly birth the brunt of wear and tear.Investing in sturdy excavators with extensive maintenance plans boosts integrity and minimizes downtime, inevitably bring about boosted performance on building sites. Therefore, recognizing the interplay in between durability and maintenance is important for any individual taking into consideration the acquisition of an excavator for metropolitan projects.Regularly Asked Inquiries

How Do Excavators Compare to Other Building And Construction Equipment?

Excavators stick out among building devices as a result of their versatility, enabling tasks such as excavating, grading, and lifting. Contrasted to others, their hydraulic capabilities provide higher effectiveness and power, making them indispensable on numerous task websites.What Safety Includes Are Consisted Of in Modern Excavators?

Modern excavators integrate numerous safety features, including rollover defense systems, alarms, and progressed presence improvements. These components collaborate to minimize risks, ensuring operator security while improving effectiveness on construction sites and various other requiring settings.

Can Excavators Be Used in Winter Conditions?

Excavators can indeed be used in winter season conditions, given they are equipped with ideal winter attachments and precautions are taken. Correct upkeep and changes improve their performance, guaranteeing efficient procedure despite difficult climate conditions.What Is the Typical Lifespan of an Excavator?

The average lifespan of an excavator generally varies from 7,000 to 10,000 hours of operation. This period can considerably depend upon maintenance practices, operating conditions, and the certain design's toughness and style attributes.Exactly how Do I Choose the Right Excavator Size for My Task?

Selecting the ideal excavator dimension involves examining task extent, site problems, and material kinds. Think about factors like reach, depth needs, and weight capacity to guarantee optimal efficiency and safety during procedure. Size matters substantially in task success. Furthermore, the reach of an excavator allows for precise excavating and material handling without repositioning the device frequently, conserving time and labor costs.Ultimately, the remarkable digging deepness and reach of excavators make them crucial for professionals seeking to finish complex jobs with accuracy and efficiency. Comfort and presence are extremely important in excavator layout, with the ergonomic seat playing an essential role in enhancing the operator's experience. The layout of an excavator prolongs beyond just the seat, with enhanced presence attributes playing a substantial duty in operator comfort and general security. Modern excavators typically incorporate adjustable seats and control settings to suit numerous operator choices, even more enhancing convenience. Light-weight materials add to reduce of transportation, making it simpler to relocate the excavator from one location to an additional within the city landscape.Additionally, numerous small excavators are outfitted with features such as extendable arms and flexible accessories, improving their performance while preserving a small size.Report this wiki page